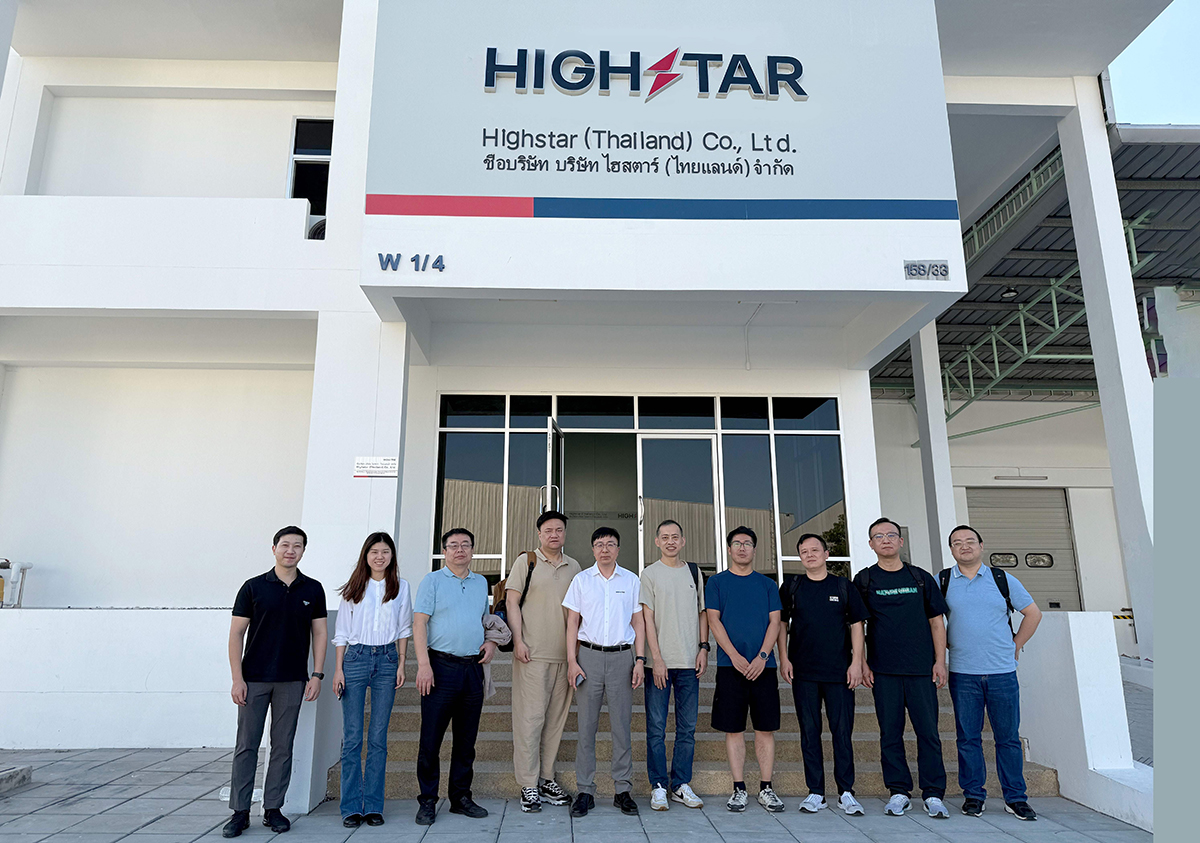

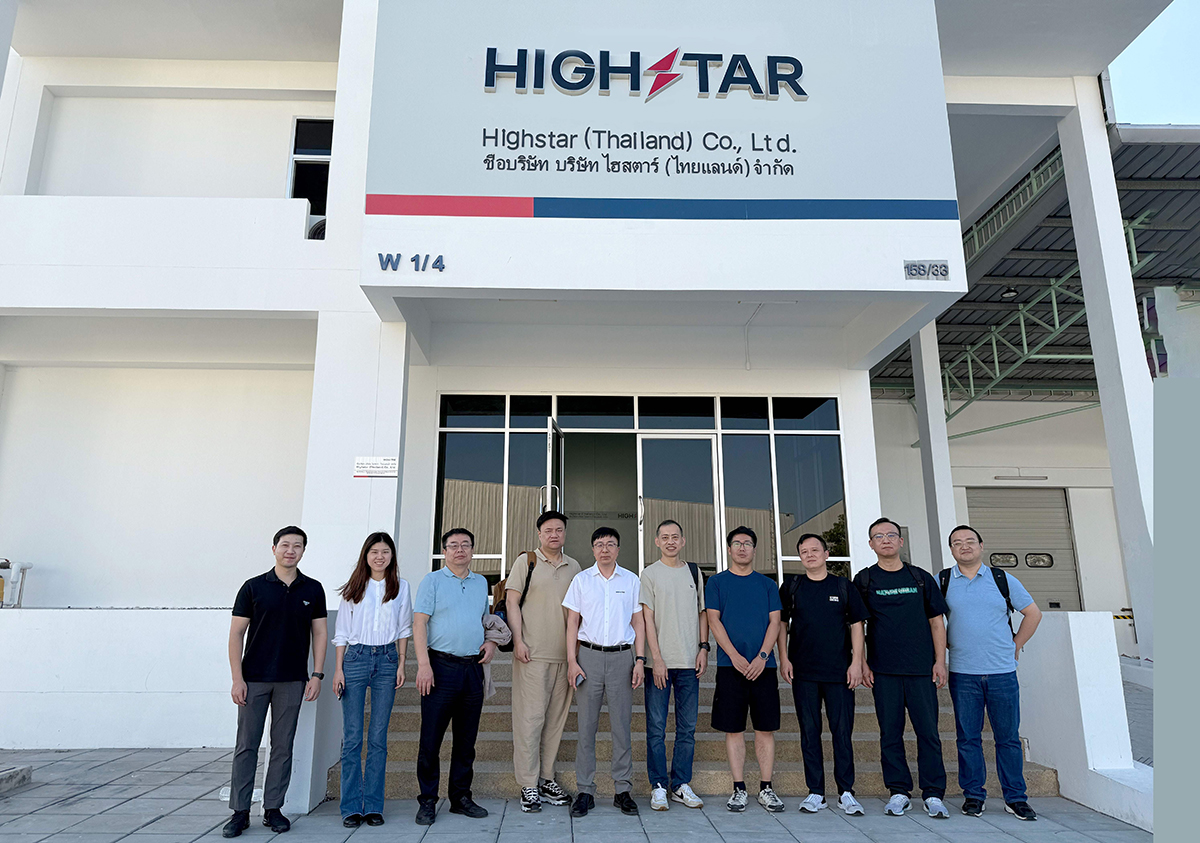

Recently, the Highstar Thailand factory has met production conditions and is about to officially commence operations. This marks a solid step in Highstar's global strategic layout and has attracted many customers of important customers to visit and exchange experiences.

The Highstar Thailand base, with a total investment area of 4,500 square meters, was completed and ready for production in January 2025. The first phase of the production lines is equipped with complete PCBA production processes, including SMT lines, wave soldering lines, and UV coating lines, focusing on the production of high-quality lithium battery protection boards. In addition, one semi-automatic and one fully automatic PACK line have been constructed, along with relevant testing and packaging equipment, for the production of lithium battery packs. In the future phase two plan, three additional fully automatic PACK production lines will be added to meet the growing order demands from overseas customers.

The factory is located near the Linchaban Port, an area with convenient transportation and well-developed logistics. Its geographical advantages ensure the efficient supply of raw materials and the rapid delivery of products, providing customers with more convenient service support.

Inside the factory, intelligent production lines operate in an orderly manner. The most advanced fully automatic PACK line assembles components with precision and efficiency, ensuring product quality and performance. The fully automatic SMT line, with its high-precision and high-efficiency chip placement process, endows the core components of electronic products with superior quality. The semi-automatic three-proof coating process provides a robust protective layer for products, ensuring stable operation in complex environments. Finally, the fully automatic packaging line ensures that products are well-protected during transportation and delivery, presenting them in the best condition to customers.

These advanced production facilities and processes have attracted numerous domestic and international customers for visits and inspections. After witnessing Highstar's professional capabilities firsthand, customers have highly praised the factory's advanced construction and the company's manufacturing capabilities. Both parties have reached preliminary cooperation intentions and have planned for additional order demands.

Meanwhile, Highstar's production base in Malaysia is also advancing steadily. It is expected that in the third quarter of 2025, two 18650 multi-tab cells production lines will be completed and put into operation. In the fourth quarter, one 21700 tabless cell production line will be completed and put into operation. In the first quarter of 2026, another 21700 tabless cell production line will be completed and put into operation. With the full release of capacity in 2026, the company is expected to achieve a sales scale of hundreds of millions. The implementation of the Southeast Asia layout will further enhance the company's delivery capabilities in overseas power tools, home appliances, energy storage, and related businesses. It is of great significance for promoting the global implementation of the company's power batteries and energy storage solutions, increasing the global market share of the company's products, and promoting the company's long-term stable development

The completion of the Highstar Thailand factory marks a new starting point on the company's path to globalization. In the future, Highstar will continue to adhere to the philosophy of "Quality First, Innovation Driven," constantly expanding into international markets and providing global customers with higher-quality products and services. Let us look forward to Highstar creating more brilliance in the global new energy field!

Buy

Buy